Madencilik sektörü, yüksek riskli operasyonlar ve zorlu çevre koşullarıyla karakterize edilen bir alan olarak dijital dönüşümden büyük ölçüde fayda sağlayabilir. Navbea, yenilikçi Gerçek Zamanlı Konum Sistemleri (RTLS) ve Nesnelerin İnterneti (IoT) teknolojileri ile sektörde dönüşümü yönlendirmektedir. Bu çözümler, güvenliği artırırken operasyonel verimliliği iyileştirir ve kaynak yönetiminde önemli avantajlar sunarak madencilik sahalarındaki riskleri en aza indirir.

Araç ve Ekipman Yönetimi

Geniş madencilik sahalarında makineleri ve ekipmanları izlemek zorlu bir iştir. Yoğun kullanım nedeniyle sıkça meydana gelen kazalar ve ekipman arızaları yaygın sorunlardır. Navbea, araçları ve ekipmanları gerçek zamanlı izleyerek yetkisiz kullanımı önleyen kapsamlı çözümler sunar. Araçların hız limitlerini aşması veya yetkisiz kişiler tarafından kullanılması durumunda uyarı sistemleri devreye girer ve güvenliği artırır. Ayrıca, telemetri özellikleri, hızlanma, frenleme ve eğim performansı gibi verileri kaydeder ve analiz eder. Bu veriler, bakım süreçlerini optimize eder ve arızaların önlenmesine yardımcı olur.

Alan Yönetimi ve Yetkilendirme

Madencilik operasyonlarında çalışanların yalnızca yetkili alanlara erişimini sağlamak, güvenlik için kritik öneme sahiptir. Madencilik sahalarının karmaşık yapısı, erişim kontrolünü zorlaştırabilir. Navbea’nın mikro-konum tabanlı yetkilendirme çözümleri, yalnızca yetkili personelin kritik alanlara girmesine izin verir. Giriş ve çıkış noktaları sürekli olarak izlenir ve yetkisiz erişim durumunda otomatik alarmlar tetiklenir. Bu sistem, güvenliği artırmakla kalmaz, operasyonel süreçlerde düzeni de sağlar.

Çalışan Güvenliği ve Sağlığı

Madencilik sektöründe çalışan güvenliği birinci önceliktir. Navbea’nın çarpışma önleme sistemleri, yapay zeka destekli kameralar ve sensörlerle donatılmıştır ve araçların yayalarla veya diğer araçlarla çarpışma riskini azaltır. Örneğin, bir yaya tespit edildiğinde, otomatik frenleme veya siren alarmları devreye girer. Ayrıca, çalışanların aktiviteleri ve sağlık durumları gerçek zamanlı olarak izlenebilir. Bu özellik, olası sağlık sorunlarının erken tespit edilmesini ve hızlı müdahaleyi mümkün kılar.

Göçük ve Çevresel Risk Yönetimi

Göçükler, yeraltı madencileri için en büyük tehditlerden biridir. Ayrıca, zehirli gaz sızıntıları ve azalan oksijen seviyeleri gibi çevresel riskler hızlı müdahale gerektirir. Navbea’nın sensör tabanlı çevresel izleme sistemi, gaz seviyeleri, sıcaklık, nem ve toz gibi parametreleri sürekli olarak takip eder. Tehlikeli koşullar tespit edildiğinde otomatik alarmlar devreye girer ve çalışanların tahliyesi sağlanır. Bu erken uyarı sistemi, çevresel tehlikelerin etkisini en aza indirir.

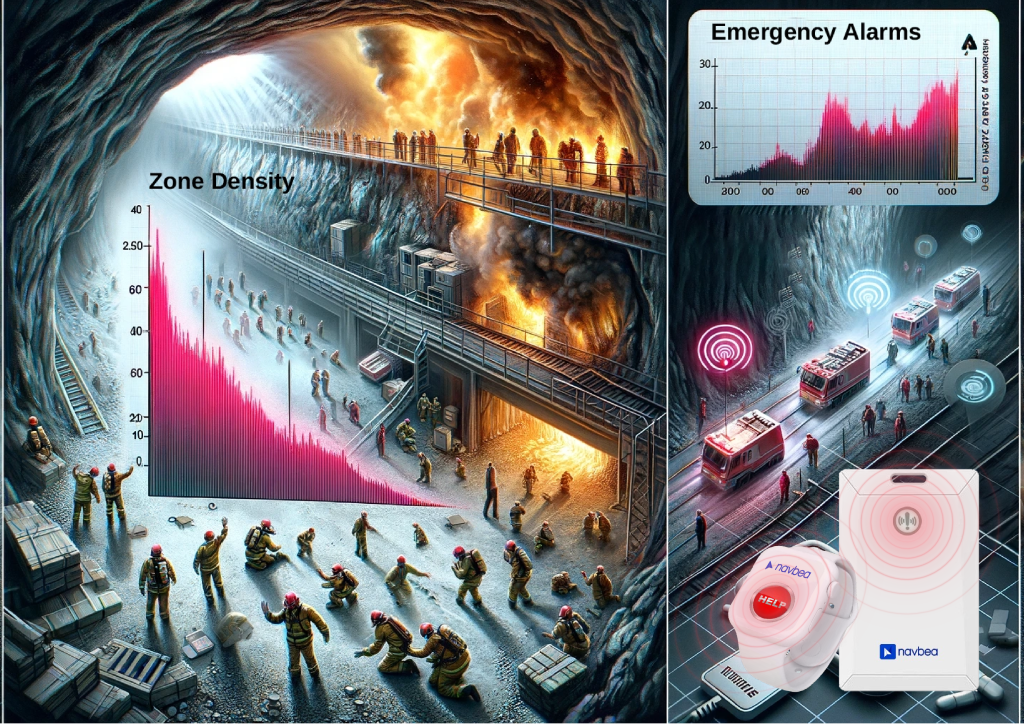

Acil Durum Yönetimi

Acil durumlarda, çalışanların güvenli alanlarda toplanmasını sağlamak kaotik bir hal alabilir. Navbea, çalışanların gerçek zamanlı konumlarını izler ve toplanma noktalarına ilerlemelerini takip eder. Bu noktalara ulaşamayan çalışanların konumları anında yöneticilere raporlanır ve hızlı müdahale sağlanır. Bu teknoloji, zamanında müdahalenin kritik olduğu durumlarda can kaybını önler ve maddi hasarı azaltır.

Navbea Çözümlerinin Avantajları

Navbea, yenilikçi çözümleriyle madencilik sektörüne güvenlik, verimlilik ve maliyet tasarrufu açısından önemli avantajlar sağlar. Gerçek zamanlı izleme ve analitik raporlama, operasyonların daha etkili yönetilmesini mümkün kılar. Çevresel risklerin erken tespiti ve çalışanların sağlık durumlarının izlenmesi gibi özellikler, güvenlik standartlarını yükseltir. Ayrıca, manuel süreçlerin otomasyonu insan hatalarını en aza indirir ve iş akışlarını optimize eder. Sürekli ekipman izleme, arızaların önlenmesini ve bakım maliyetlerinin düşürülmesini sağlar.

Madencilik sahalarında ATEX sertifikalı ekipman kullanımı yasal bir zorunluluktur. ATEX sertifikalı cihazlar, patlayıcı ortamlar için güvenli çalışma sağlar ve kıvılcım, aşırı ısınma ve elektriksel arıza gibi riskleri en aza indirir. Bu cihazlar, suya, toza ve darbelere karşı dayanıklılık sağlayan IP67 standartlarına da uygundur ve madencilik uygulamaları için güvenilir ve dayanıklıdır. ATEX uyumlu ekipman kullanımı, çalışan güvenliğini artırır ve yasal düzenlemelere uyumu sağlar. Navbea, ATEX sertifikalı ürünleriyle madencilik sahalarında RTLS sistemlerinin uygulanmasını mümkün kılar.

Soma Kömür Madeni Faciası Perspektifinden Navbea Çözümleri

Türkiye’de 2014 yılında yaşanan Soma kömür madeni faciası, yetersiz güvenlik sistemlerinin felaket sonuçlarını ortaya koymuştur. Bir yangın sırasında salınan karbon monoksit 301 madencinin hayatını kaybetmesine neden olmuştur. Navbea’nın çözümleri, bu tür trajedileri önlemede kritik bir rol oynayabilir. Gerçek zamanlı çalışan takibi, tehlike altındaki kişilerin hızlıca tespit edilmesini sağlar. Yetkilendirme sistemi, yalnızca yetkili personelin kritik alanlara erişmesini sağlayarak riskleri en aza indirir.

Sonuç

Navbea, madencilik sektörünün en büyük zorluklarına yenilikçi ve etkili çözümler sunarak dijital dönüşüme öncülük etmektedir. Gerçek zamanlı izleme, çevresel risk izleme ve acil durum yönetimi gibi özellikler, iş sağlığı ve güvenliğini iyileştirirken operasyonel süreçleri optimize eder. Soma gibi gelecekteki trajedileri önlemek için dijital dönüşüm teknolojilerinin benimsenmesi zorunludur. Navbea’nın RTLS ve IoT tabanlı çözümleri, güvenlik standartlarını yükseltir ve maliyetleri düşürerek şirketi madencilik sektöründe güvenilir bir ortak haline getirir.